2019 New Big Capacity Automatic Oatmeal Flakes Processing Line

Production line main Features

- full automatic processing line

- Machine used food grade Stainless steel

- Extruder self-cleaning, ensure food hygiene and save operating cost

- Longer working life

- Puffed food through extruder to arrive high temperature sterilization, ensuring food security

Flow chart:

mixer-screw conveyor-twin screw extruder-vibrating feeder-drum type dryer-air conveyor- flaking machine-air conveyor-dryer-hoister-vibrating feeder-high temperature inflated oven-flavoring line-dryer-cooling machine

Whole production line technical parameter:

| Model | Installed Power | Power Consumption |

Output | Size (L*W*H) |

| 65-II | 134kw | 94kw | 125-140kg/h | 17000x1100x2500mm |

| 70-II | 136KW | 95kw | 200-230kg/h | 17300x1200x2600mm |

| 65-II | 74kw | 52kw | 125-140kg/h | 16000x1100x2500mm |

| 70-II | 76kw | 53kw | 200-230kg/h | 16300x1200x2600mm |

Satisfied service & Turnkey Solution:

- Before Purchasing: We will provide professional technical project, design service and sales consultation service to solve the customers' question and worried;

- During Production: Timely updates the machine status for customer to ensure delivery time, and quality;

- After Production: Machine testing video and photos will be provided for inspection, if the customer can't come;

- Before & During Shipment: The machine will be cleaned and packaged before transportation; All the documents will be provided for the seller;

- Installation & Training: Providing professional and expert technical engineers to supply the training and installation service;

- After Sales Service: Dedicated department and engineers for providing the timely and efficient service when the clients' need, such as formula, parameters setting, and spare parts.

Machine packing & Shipping

- All Machine will be cleaned and whole wraped by plastic film to avoid any scratch;

- Extra Spare Parts,wires and tool box will be placed with the package;

- Delivery Department and sales will check the list to avoid any missing;

- All Wooden Cases for protecting the machine during long-time shipment

Flakes processing line Part Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| No. | D | d | Inventory | Minimum Buy Quantity | Weight | B | EAN | |

| 53407 | 80 mm | 35 mm | - | - | 0.790 Kg | - | - | |

| QVCW16V300SEB | 3.29 Inch | 83.566 Millimeter | 3 Inch | 76.2 Millimeter | 0.0 | N/A | 9.988 | - | 0883450038522 | |

| 6409-3ZZC3 | - | - | 0.0 | N/A | - | - | 0605790371394 | |

| M238849DW-90095 | 10.625 Inch | 269.875 Millimeter | 7.375 Inch | 187.325 Millimeter | 0.0 | N/A | 20.603 | - | 0053893539164 | |

| 23252 CC/C2W33 | - | - | 0.0 | N/A | 0 | - | - | |

| 854D | - | - | 0.0 | N/A | 0 | - | 4547359457803 | |

| FPSR2-58 | 3.6250 in | 0.6250 in | - | - | - | 2.7031 in | - | |

| NH410 | 130 | 50 | - | - | - | 31 | - | |

| 22208 KCW33+H308 | 80 mm | 40 mm | - | - | - | 23 mm | - | |

| 3315-2RS | 160 mm | 75 mm | - | - | - | 68,3 mm | - | |

| 68/850/1080 | 1080,000 mm | 850,000 mm | - | - | - | 82,000 mm | - | |

2019 New Big Capacity Automatic Oatmeal Flakes Processing Line Part Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| No. | d | D | Weight | C | Inventory | Minimum Buy Quantity | B | |

| 30206 | 30 mm | 62 mm | 0,22 Kg | 47,5 kN | - | - | 16 mm | |

| 30321D | 105 mm | 225 mm | 8,76 Kg | 339 kN | 0.0 | N/A | 49 mm | |

| 23972-MB | 14.173 Inch | 360 Millimeter | 18.898 Inch | 480 Millimeter | 46.5 | - | 0.0 | N/A | 3.543 Inch | 90 Millimeter | |

| FW129 | - | - | 0.648 | - | 0.0 | N/A | - | |

| UCFL205-100D1 | - | - | 0.63 | - | 0.0 | N/A | - | |

| SNS3136-H-D | - | - | 0 | - | 0.0 | N/A | - | |

| SSMR-104-ZZ | - | - | 0.01 | - | 0.0 | N/A | - | |

| SF-22C CR | 1.3750 in | 3.6250 in | - | - | - | - | 4.6250 in | |

| FTRE-4.50 | - | 5.4375 in | - | - | - | - | - | |

| 02876 | 1.2500 in | - | - | - | - | - | - | |

| 6209T1XZZ | 45 mm | 85 mm | - | 19 mm | - | - | 19 mm | |

| 6706LLF | 30 mm | 37 mm | - | 4 mm | - | - | 4 mm | |

Customer Cases For Flakes processing line For Factory In 2022 | |

|---|---|

| 1 | China Automatic Breakfast Cereal Corn Flakes Maker Machines Hot Selling Cereal Corn Flakes Processing Line For Sale Sri Lanka |

| 2 | Roasted Corn flakes processing machine Corn flakes manufacturing machine Corn flakes processing line Sale In Morocco |

| 3 | Semi Automatic Scale Frozen Potato Flakes dicing machine Chips Processing Plant Making Machines French Fries Production Line Sale In Sri Lanka |

| 4 | Spray Sugar Corn Flake Breakfast Cereals Snacks Processing Line Process In Singapore |

| 5 | crispy corn tortilla breakfast cereal production line corn flakes making machine food processing machinery For Sale Algeria |

| 6 | Stainless Steel Processing Machine Line To Make Corn Flakes Food For Sale Malaysia |

| 7 | Haitel Automatic Oat flakes Making Machine For Sale Nigeria |

| 8 | Automatic Fresh flake processing line Potato Flake Production Line Sale In United Arab Emirates |

Customer Cases For Flakes processing line For Factory In 2022 | |

|---|---|

| 1 | Cocoa puffs breakfast cereals corn flakes maker coco ball leisure nutritional cereal production line processing For Sale Nigeria |

| 2 | Small Home Use Wheat Oats Maize Corn Flakes Making Machine Price Process In Singapore |

| 3 | Best quality Breakfast Cereals processing line corn flakes production line machinery Sale In Sri Lanka |

| 4 | Automatic corn flakes production line/breakfast cereals corn flakes making Machine Equipment For Sale United Arab Emirates |

| 5 | multi-functional potato chips making machine Crisp Chips production line from Shanghai machinery For Sale Sri Lanka |

| 6 | Fully Automatic Breakfast Cereals/Corn Flakes Making Machine/Processing Line Process In Zimbabwe |

| 7 | Automatic Breakfast Cereal Production Line Rolled Oats processing line Process In Zimbabwe |

2019 New Big Capacity Automatic Oatmeal Flakes Processing Line Project Price List | |||

|---|---|---|---|

| Product | Quantity | Min Price ($) | Max Price ($) |

| Snack Food Oats Corn Flakes Processing Line Machine | 1 Set | US$1086 | US$7294 |

| Corn Chips Flakes Snack Food Processing Production Line | 1 Set | US$1404 | US$6641 |

| Experienced Oatmeal Flakes Breakfast Cereals Processing Line | 1 Set | US$1650 | US$5609 |

| 100 T / D Corn Flakes Processing Line Corn Processing Equipment | 1 Set | US$1504 | US$6292 |

| Automatic Extrusion Breakfast Cereal Corn Flakes Processing Line corn flakes production line | 1 Set | US$1281 | US$5747 |

| Breakfast Extruded Cereal Flake Processing Line | 1 Set | US$1950 | US$5111 |

2019 New Big Capacity Automatic Oatmeal Flakes Processing Line Video

Potato Flakes Processing Line | Wintech Taparia

Potato Flakes · Process Equipment For Potato Flake Plant · Washing and Peeling · Prewasher with Destoner (Cyclone type) · Abrassive Peeler x 2 Nos. · Roller ...

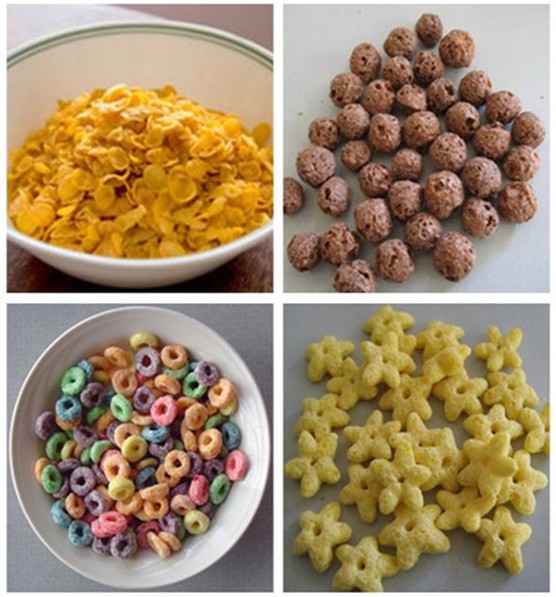

Corn Flakes Production Line - Extruded Food Equipment ...

The corn flakes production line uses corn flour or other grains as materials to produce breakfast cereal corn flakes through raw material mixing, extrusion, ...

Corn Flakes Production Line - SHANDONG LOYAL ...

As a corn flake production line manufacturer, loyal's small corn flakes making machine design drawing is summed up by a number of flakes making machine ...7 days ago · Uploaded by Shandong Loyal Industrial Co.,Ltd.

Breakfast cereals - Clextral

Our twin-screw extrusion lines process ready-to-eat breakfast cereals with a wide ... cereals and flakes, to co-extruded (filled) and bicolored cereals.

Corn flakes extruder / production line

Production Line/Process of Corn Flakes up to 200 kg/h (possibility to propose from 100 kg/h up to 800 kg/h). Screw feeding conveyor; Sifter; Mixer ...

Potato flakes - Process lines | Kiremko

Whether potato flakes are your primary product or whether they are a by-product of your other potato (or other) production lines, our machines will deliver ...

Compact Potato Flakes Production Line - Kiron Food ...

Potato flakes are flat chunks of dehydrated mashed potato. Potatoes are cooked and mashed, then crushed by rollers on the surface of a drum.

Breakfast Cereal Corn Flakes Processing Line - Excellent ...

Construction of Breakfast Cereal Corn Flake Processing Line: · 1.Flour mixer · 2.Spiral Elevator · 3.Extruder · 4.Cooling Vibration · 5.Air Conveyor · 6.Spreading & ...