Experienced Oatmeal Flakes Breakfast Cereals Processing Line

Product Description

Process:

Cooking→Pre Drying→Flaking→Oven→Cooling→Packaging

Cooking Machine

inactivation and sterilization; make the product ready for instant or quick cooking;

make the oats moist, soft and easy to squash. Features: fully cooking, simple operation

Hoister

Hoist the product into dryer

5Meters 5Layers Gas Dryer

Five meters five layers gas circulation oven is a horizontal dryer, with natural gas heating the

air as the medium, the cross flow (air flow direction and the direction of the material were "ten"

cross shaped) drying method, Heat exchange between the material and the hot air in the dryer,

in order to go out excess moisture the product to reach the required water requirements.

Working process

1) upstream of the extruded material on the conveyor belt through the distributor evenly

scattered;

2). puffed material is brought into dryer with conveying;

3). the hot air from the circulation air enters the drying section and passes through the material

on the conveyer belt to realize the hot and humid exchange between the material and the hot

air;

4) return the dry material at the return section;

5). after five dry material discharge in the dryer outlet.

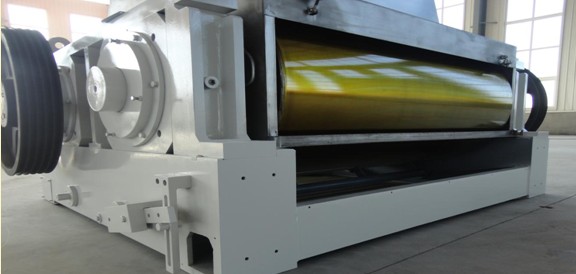

Flaking Machine

Squeeze the oatmeal with a couple of rollers.

The oatmeal is made into a sheet of specified density flakes. The principle is actually a process of starch

gelation, the digestibility of the corn starch is enhanced. In addition, the chemical structure of Size 1.5×1.4×1.7 m

Power:18 kwproteins in maize is changed during tabletting, which is beneficial to the absorption of protein by stomach. The mechanical action of a roll is a process of crushing to achieve a specified density.

High Temperature Continuous Oven

Structure: mainly by the conveyor system, gas head and control system composed of three major parts.

Features:Multi section independent temperature control, uniform temperature in the furnace. The speed regulation or the electric conveying speed, the frequency conversion speed regulation, the adjustment is free, the movement is steady, the production efficiency is high.

5Meters 5Layers Cooler

Use the net belt to deliver the product, and use the fan air from top to bottom to cool during the transmission, for easy packing

Packaging Machine

Packing.

Product Feature

Adjustable speed, continuous work, Stainless steel rack, food grade PVC conveyor belt.

Technical Parameter

| Machine Material | Stainless Steel |

| Voltage | 380V/50Hz |

| Total Installed Capacity | 77kw |

| Workshop Space Requirement | 300-600 m2 |

| height above | 3.5 meters |

| Workers | 3-5 |

| Total output | 300-500kg/h |

Flakes processing line Part Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| No. | d | D | B | Diametro esterno | db - Cone Backface Backing Diameter | da - Cone Frontface Backing Diameter | r - Cup Backface To Clear Radius2 | |

| 6203.FT150ZZ | 17 mm | 40 mm | 12 mm | - | - | - | - | |

| PU335Z511 | 2.188 Inch | 55.575 Millimeter | 3.063 Inch | 77.8 Millimeter | 3.5 Inch | 88.9 Millimeter | - | - | - | - | |

| ECOP040604 | - | - | - | - | - | - | - | |

| H3144XX715 | 7.9375 in | - | - | - | - | - | - | |

| 1975 - 1931-B | 0.8750 in | 2.3750 in | - | - | 1.2 in | 1.16 in | 0.030 in | |

| H239649 - H239610 | 187.325 mm | 319.964 mm | 88.900 mm | - | 214.12 mm | 204.98 mm | 4.83 mm | |

| BGFSC6004ZZ-[45-80/1] | - | - | - | - | - | - | - | |

| 204-mff | 20.000 mm | 47.0000 mm | 14.00 mm | - | - | - | - | |

| NUP2205EG15 | 25,000 mm | 52,000 mm | 18,000 mm | 52,000 | - | - | - | |

| 6904LLU | 20 mm | 37 mm | 9 mm | 1.457 Inch | 37 Millimeter | - | - | - | |

Experienced Oatmeal Flakes Breakfast Cereals Processing Line Part Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| No. | d | D | Weight | B | Inventory | Minimum Buy Quantity | C | |

| 51202 | 15 mm | 32 mm | 0,046 Kg | - | - | - | 16,5 kN | |

| NU211E | 55,000 mm | 100,000 mm | - | 21,000 mm | - | - | 21,000 mm | |

| EXT209T20COE | 45 mm | - | 2.55 kg | 42.8 mm | - | - | 31.85 kN | |

| USFC211T20CO | 55 mm | - | 3.88 kg | 45.3 mm | - | - | 43.55 kN | |

| QAAPF22A407SEM | 4.438 Inch | 112.725 Millimeter | 6.25 Inch | 158.75 Millimeter | 32.688 | 4.75 Inch | 120.65 Millimeter | 0.0 | N/A | - | |

| QMTU11J055SEN | 2.165 Inch | 55 Millimeter | - | 8.172 | - | 0.0 | N/A | - | |

| UCHA 202 10 | 0.625 Inch | 15.875 Millimeter | 1.221 Inch | 31.013 Millimeter | 0.77 | 2.5 Inch | 63.5 Millimeter | 0.0 | N/A | - | |

| 22228YMW33 | - | - | 0 | - | 0.0 | N/A | - | |

| 440-20024/432-20024 | - | - | 0 | - | 0.0 | N/A | - | |

| 29502-2824 | - | 3.2500 in | 0.25 lb | - | - | - | - | |

| 51320-nsk | 100mm | 170mm | - | 55mm | - | - | - | |

| K40×47×20 | - | - | - | - | - | - | - | |

| 6920N | 100 mm | 140 mm | - | 20 mm | - | - | 20 mm | |

Customer Cases For Flakes processing line For Factory In 2022 | |

|---|---|

| 1 | Automatic Fresh flake processing line Potato Flake Production Line Sale In Malaysia |

| 2 | Roastered corn flakes processing machinery For Sale Zimbabwe |

| 3 | double screw extruder crunchy cereal corn flex processing line Sale In Sri Lanka |

| 4 | Flakes Processing Line Machine The Corn Flakes Corn Flakes Food Machinery Corn Flakes Processing Machine Corn Flakes Processing Line Plant For Sale Nigeria |

| 5 | breakfast cereal food processing line extruder automatic corn flakes making equipments Process In Algeria |

| 6 | Snack Food Production Line Processing Equipment Washing Sweet Potato Chip Making Machine For Sale Sri Lanka |

Customer Cases For Flakes processing line For Factory In 2022 | |

|---|---|

| 1 | China Automatic Breakfast Cereal Corn Flakes Maker Machines Hot Selling Cereal Corn Flakes Processing Line Sale In Nigeria |

| 2 | Kellogg's Breakfast cereals choco corn flakes processing line from professional supplier For Sale United Arab Emirates |

| 3 | Flakes Bread Crumb Making Machine Snowflakes Bread Bran Bread Crumb Extruder Production Line For Sale Malaysia |

| 4 | Kellogg's Corn Flakes Production Line Sale In Morocco |

| 5 | Corn flakes/corn chips making/production/processing machines line For Sale Nigeria |

| 6 | Small Scale Semi Automatic French Fries Production Line Frozen Potato Flakes Chips Processing Plant Making Machines For Sale For Sale Singapore |

Experienced Oatmeal Flakes Breakfast Cereals Processing Line Project Price List | |||

|---|---|---|---|

| Product | Quantity | Min Price ($) | Max Price ($) |

| Corn Chips Flakes Snack Food Processing Production Line | 1 Set | US$1029 | US$7419 |

| 2019 New Big Capacity Automatic Oatmeal Flakes Processing Line | 1 Set | US$1320 | US$7819 |

| Breakfast Extruded Cereal Flake Processing Line | 1 Set | US$1163 | US$7134 |

| 100 T / D Corn Flakes Processing Line Corn Processing Equipment | 1 Set | US$1186 | US$6792 |

| Snack Food Oats Corn Flakes Processing Line Machine | 1 Set | US$1823 | US$5672 |

| Automatic Extrusion Breakfast Cereal Corn Flakes Processing Line corn flakes production line | 1 Set | US$1219 | US$5665 |

Experienced Oatmeal Flakes Breakfast Cereals Processing Line Video